VMC Programmer

Job Summary

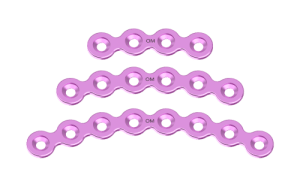

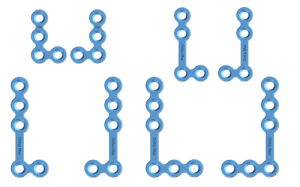

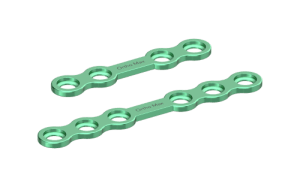

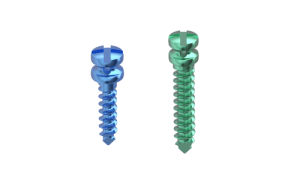

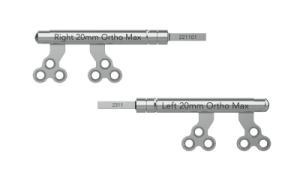

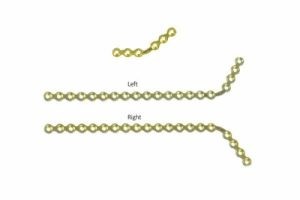

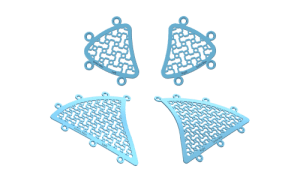

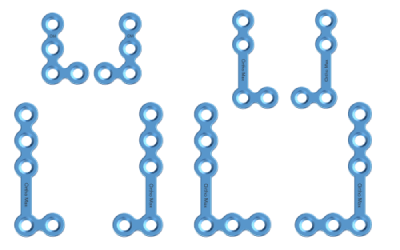

We are seeking an experienced, detail-oriented, and technically strong VMC Programmer to support precision machining operations at our manufacturing facility. The ideal candidate will be responsible for creating, modifying, and optimizing CNC programs for Vertical Machining Centre (VMC) machines to ensure high-quality production of orthopedic implants.

This role requires strong analytical skills, in-depth knowledge of CNC programming, and the ability to work closely with operators, setters, Quality, and Engineering teams in a regulated medical device manufacturing environment.

Responsibilities

As a VMC Programmer, the responsibilities shall include, but are not limited to:

- Creating, modifying, and optimizing CNC programs (G-code / M-code) for VMC machines as per production requirements.

- Interpreting complex engineering drawings, GD&T specifications, and CAD models to develop efficient machining strategies.

- Selecting appropriate cutting tools, fixtures, machining sequences, speeds, feeds, and parameters to achieve optimal performance.

- Simulating and verifying toolpaths using CAM software (preferably Siemens NX) to prevent machine collisions and errors.

- Coordinating with VMC Setters and Operators for program trials, prove-outs, and machining improvements.

- Ensuring all programs produce components within tight tolerances and meet defined quality standards for orthopedic implants.

- Troubleshooting programming, tooling, and machining issues to minimize downtime and scrap.

- Supporting continuous improvement initiatives related to cycle time reduction, tool life optimization, and machine efficiency.

- Maintaining program files, setup sheets, revision control, and related technical documentation.

Working closely with Quality and Engineering teams during validation, inspection feedback, and corrective actions.

Experience & Qualifications

Experience:

- Minimum 3 to 6 years of experience as a VMC Programmer

Preferably from orthopedic implants, medical devices, or precision engineering manufacturing

Education:

- Diploma / BE / BTech in Mechanical Engineering, OR

ITI with strong hands-on CNC programming experience

Technical Skills & Competencies

- Strong proficiency in CNC Programming for VMC machines

- Hands-on experience with CAM software (Siemens NX preferred)

- In-depth knowledge of G-code / M-code

- Understanding of GD&T and precision machining principles

- Knowledge of tooling, fixtures, machining parameters, and process optimization

- Familiarity with medical device quality standards and documentation practices

- Ability to independently handle complex components and lead technical discussions

Soft Skills

- Strong analytical and problem-solving abilities

- High attention to detail and process discipline

- Good communication and documentation skills

- Ability to work independently and collaborate across departments

Role Details

- Role: VMC Programmer

- Industry Type: Medical Devices & Equipment

- Department: Production / Manufacturing / Engineering

- Employment Type: Full Time, Permanent

- Role Category: CNC Programming & Precision Manufacturing

Interested Candidates can share their resume at:

Education

- UG: Bachelor of Technology / Bachelor of Engineering (B.Tech/B.E.) in Mechanical Engineering, Diploma in ITI

Interested candidates can share their resume at: hr@orthomaxindia.net